Overview of the Approach for Implementation

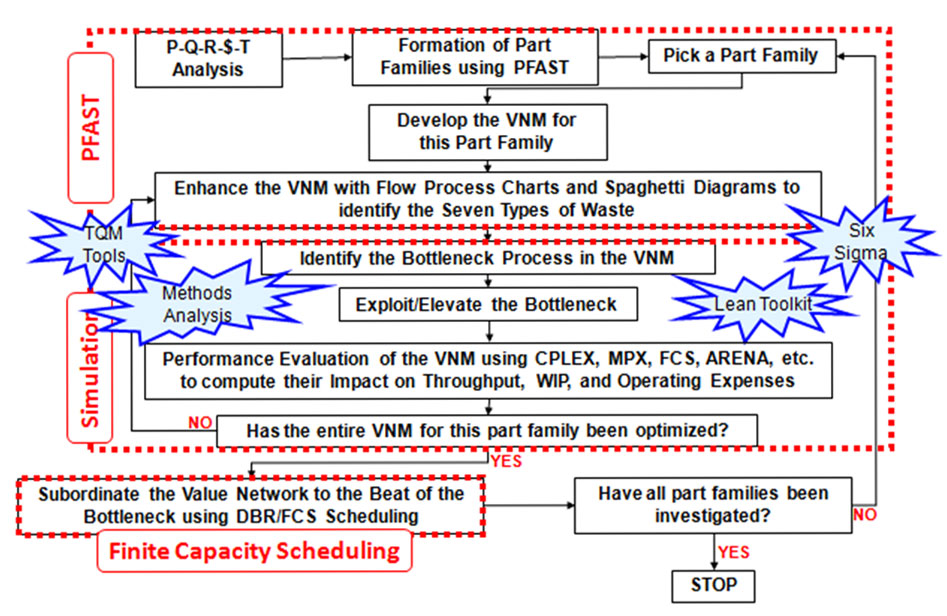

First, it is essential that the factory layout be changed with appropriate modifications in shop floor logistics. Figure 1 presents a flowchart for the approach to implementing JobshopLeanLean based on the Womack-Jones process for implementing Lean. Every iteration of the process shown in Figure 1 is expected to yield a stand-alone flexible manufacturing cell to produce a part family. In practice, several real-world constraints will need to be “broken” to ensure that each cell can be implemented. Typically, any HMLV facility will end up being divided into at least two areas:

- One area consisting of flexible manufacturing cells with each cell dedicated to a product family

- Another (separate) area where the spare parts, prototypes and one-off orders will be produced.

Next, it is important that an HMLV manufacturer invest in “re-tooling” their ERP (Enterprise Resource Planning) system. They could do this either by activating additional modules that are already available from their ERP vendor or acquire third party software add-ons. Table 1 lists some of the add-ons that an ERP system must have in order to become capable of managing operations in any HMLV facility.

Table 1 ERP Add-Ons to Replace the TPS/Lean Tools that are Unsuitable for HMLV Facilities

Table 1 ERP Add-Ons to Replace the TPS/Lean Tools that are Unsuitable for HMLV Facilities

|

TPS/Lean Tool not for HMLV Manufacturing |

ERP Add-Ons to Replace the TPS/Lean Tool |

|

Value Stream Mapping |

|

|

Assembly Line Balancing |

Implement Manufacturing Cells:

|

|

FIFO Sequencing at Work Centers |

Job Sequencing at Work Centers driven by priorities other than FIFO ex. Earliest Due Date, Common Setup, Kit of Parts, Available Capacity on Work Center (especially if it is a bottleneck), etc. |

|

Product-specific Kanbans |

|

|

Inventory Supermarkets |

|

|

Work Order Release based on Pitch |

|

|

Mixed Model Production with Level Loading |

|

|

Pacemaker Scheduling |

|

|

Work Center Loading with Takt Time |

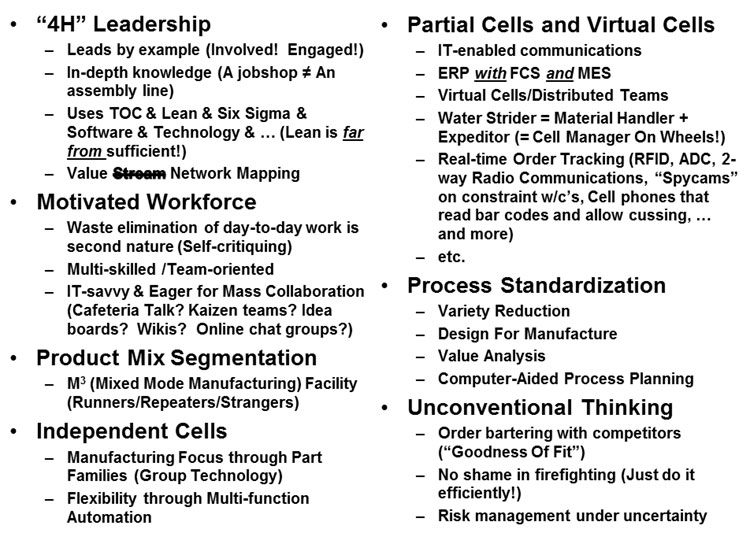

Finally, there are many supporting activities that are essential to successfully implement JobshopLean, as shown in Figure 2. Perhaps the biggest obstacle to the success of JobshopLean is the failure of members of upper management to be “4H” (Head, Heart, Hands, Hoofs) leaders. Per my experience, in the case of the typical SMM, the persons who fill the roles of CEO, President, VP-Operations, Director-Operations and Plant Manager need to be students of Lean (“Head”), have compassion and caring for their employees (“Heart”), be hands-on and participate in employee-led improvement activities (“Hands”) and make it a point to do gemba walks on a regular basis (“Hoofs”).

Strategic Projects to Implement JobshopLean

Here is a “no brainer list” of strategic projects that I immediately execute first-and-foremost to achieve Flow:

- Involve the Company Leadership: Too often, the President/Owner of the company, the VP-Operations and the Plant Manager take a hands-off attitude towards the implementation of Lean. Not only should these individuals participate in the day-to-day efforts of the work force and CI team tasked with the Lean implementation, they should demonstrate commitment. For starters, they should commit to gemba walks, a monthly town hall meeting and “Attaboy, keep it up!” recognition of employees.

- Design the Overall Factory Layout: A Factory Flow Analysis (FFA) using a representative sample of components (or products), especially the Runners and Repeaters in the product mix, is essential. This analysis will yield a Spaghetti Diagram that connects all processing departments such as Raw Material Stores (Receiving), Machining, Fabrication, Inspection, Finished Goods (Shipping), etc. including product flows to/from Suppliers. I firmly believe that, if the existing layout prevents Flow, then all justifiable equipment moves must be executed, especially if there is a plan to introduce new equipment and/or manufacturing technology into the existing factory. This project will give ample opportunities to engage the employees to undertake kaizens to implement workplace improvements to complement the equipment moves. These kaizens will rely heavily on Lean tools such as Setup Reduction, Quality Improvement and Ergonomics!

- Improve Throughput in the Bottleneck Department: This project involves the Exploit the Constraint step in the 5-step POOGI (Process of Ongoing Improvement) to implement TOC (Theory Of Constraints). It would (a) determine the true capacity utilization of the equipment in the department, and primary reasons why the utilization is ≤ 80%-85%, (b) assess if the ERP system has the relevant data for each equipment that is essential to calculate daily work load i.e. setup time, cycle time, scrap rate, OEE , etc., (c) question the due dates and sequencing rules that influence the sequence in which jobs are processed, (d) evaluate the manpower levels in each shift and operator skills that determine job assignments, (e) prevent pre-mature release of jobs to the floor by Sales & Customer Service, etc. This project will give ample opportunities to engage the employees to undertake kaizens to implement workplace improvements to complement the equipment moves. These kaizens will rely heavily on Lean tools such as Setup Reduction, Quality Improvement and Ergonomics!

- Synchronize Factory Operations to Improve Throughput in the Bottleneck Department: This project involves the implementation of the remaining steps Subordinate the system to the Constraint and Elevate the Constraint steps in the 5-step POOGI (Process of Ongoing Improvement) to implement TOC. This is when the DBR (Drum-Buffer-Rope) method of Pull Scheduling, aka CONWIP ought to be attempted. The hardest most-needed capability that any HMLV manufacturer lacks is the ability to produce a feasible daily operations schedule because it is based on finite capacity constraints. The typical ERP system that is available commercially cannot schedule because it uses MRP (Material Requirements Planning) for production planning and operations scheduling! Please check out the websites of FCS (Finite Capacity Planning) systems that could be bolted on to your ERP system!

- Increase Order Flow Velocity with Shop Floor Control: It is well known that 95% of the total time that the typical order spends on the production floor is non-value added time, especially waiting and transportation times! Recall what Ohno said “All we are doing is looking at the time line, from the moment the customer gives us an order to the point when we collect the cash. And we are reducing the time line by reducing the non-value adding wastes”. This project aims to establish complete “situational awareness” of all active orders on the floor to minimize WIP throughout the factory floor. Implementing Manufacturing Cells, Water Striders, an Order Tracking Board, Mobile Communications and Daily Morning Huddles will deliver results!

- Engage the Employees: The implementation of the strategic projects #2 through #5 will automatically surface opportunities for employees to undertake small CI (Continuous Improvement) projects within their work areas. However, rather than give generic training on the Lean tools, I prefer offering customized training appropriate to the CI (Continuous Improvement) projects being done.

- Convince Management to Hire Industrial Engineers: For 22 years, I was an IE teacher and researcher at a Tier 1 research university. Not a single one of my JobshopLean projects in industry would have succeeded had I not had one or more IE student interns working full-time at each client site!

Connecting the Strategic Projects to Employee-led Kaizens

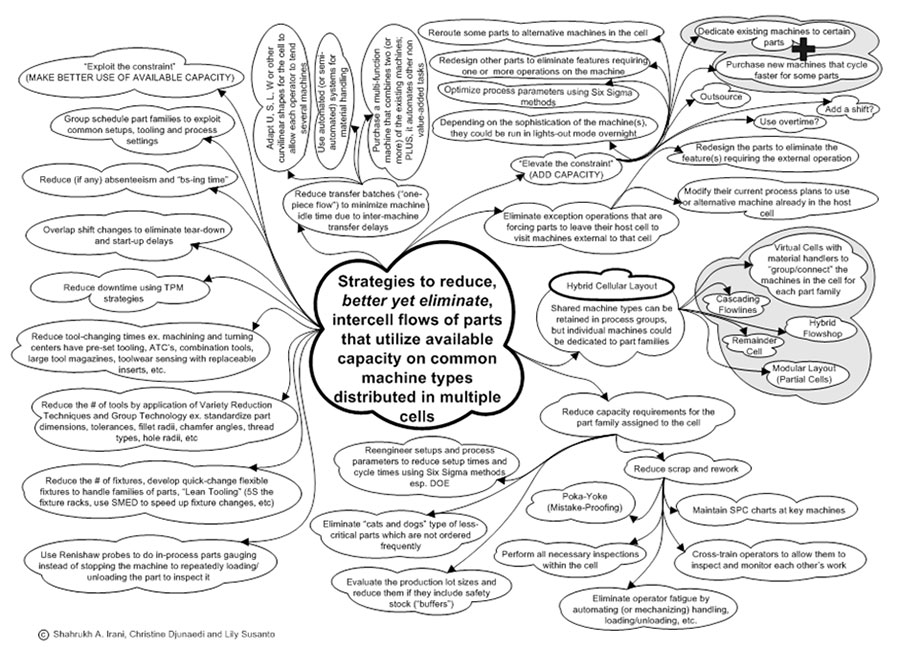

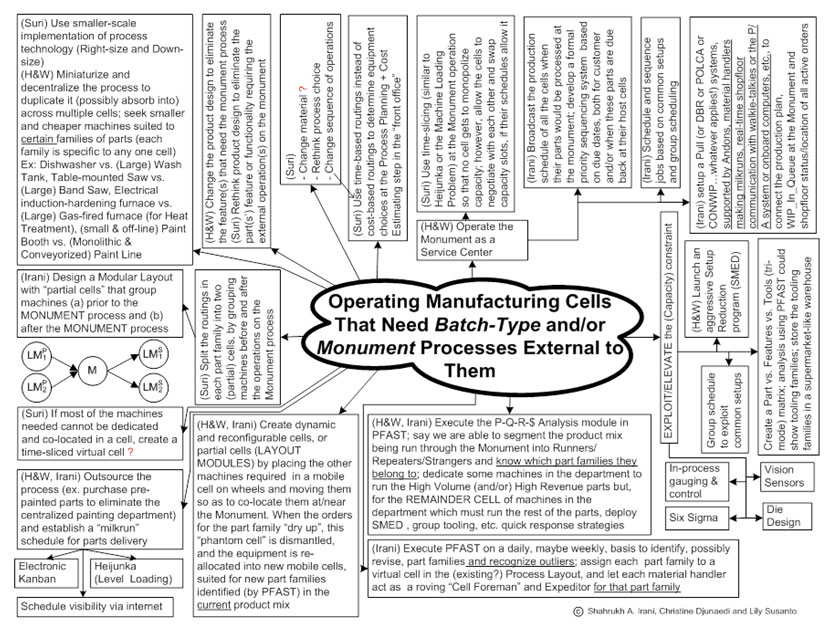

As learned from the revolutionary Toyota Production System, a key aspect of implementing JobshopLean is to engage the employees to do CI (Continuous Improvement) kaizens that support the strategic projects. Recall that the foundation for achieving Flow in a HMLV factory is to design a Cellular Manufacturing System to replace the existing layout of the factory. But it is rare that any HMLV factory is amenable to a complete decomposition into stand-alone independent cells! When cells are infeasible, then appropriate projects should be executed to eliminate the constraints that prevent the implementation of cells. Figure 3(a) and Figure 3(b) summarize the strategies that can be used to eliminate the constraints to implementing cells. Many of these strategies are the standard Lean tools that are universally applicable!

Additional Reading

A quick-start approach for implementing Lean in jobshops. Gear Technology, (2012, October), 10-16.

Danford, M. From job shop chaos to Lean order. Modern Machine Shop, (2010, November), 60-67.

Wang, B. (2007). The quick-start approach to JobshopLean: How to initiate the implementation of Lean in a high-mix low-volume manufacturing facility. Bryan submitted this paper for the Student Paper Competition sponsored by the Lean Division of the Institute of Industrial and Systems Engineers. Click here to see the video that he made to document his internship at Bula Forge & Machine Inc.